brinell hardness test formula derivation|brinell hardness testing machine diagram : trade The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry. In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter.

28 de jun. de 2022 · 26 de Fevereiro de 2024 - Ano 10. NOTÍCIAS. Plantão Policial. 28/06/2022. Mulheres julgadas e condenadas pelo tribunal do crime são castigadas .

{plog:ftitle_list}

20 de dez. de 2023 · O filme encerrará o universo de heróis no cinema com aventura divertida, mas nada memorável. Saiba mais sobre a trama, os efeitos e a direção de .

Working out the best and most suitable hardness tests to incorporate in your test and measurement process? Looking to find out more about where the Brinell method is useful and how to calculate the results? Read on for some top tips. See more

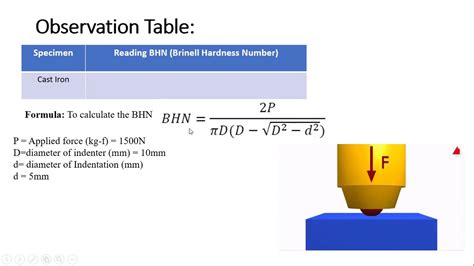

Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. See moreWhen measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being . See moreThe approximate Brinell number for loads are: While the Brinell hardness test is most commonly used to test metals and alloys, it can be used on other . See more Derivation of brinell hardness number (BHN);Brinell Hardness Test complete analysis from exam point of view.Video covers everything in brief and to the point.

The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry. In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell hardness test is commonly used to determine the hardness of materials .

how to calculate brinell hardness

https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.The Brinell hardness test uses a hardened steel ball indenter that is pushed into the material under a specified force. The diameter of the indentation left in the surface of the material is measured and a Brinell hardness number is calculated from this diameter.The Brinell Hardness Number HB is computed from the equation: where. P is the applied load of 3,000, 1,500, or 500kg. D is the diameter of the ball in mm. (10mm) d is the mean diameter of the indentation in mm. The units of HB are kg/mm^2. However, the results are usually reported .

Equation. The following is the equation for the Brinell hardness number: HB = where F is the applied load in kilograms, D is the diameter of the indentor in millimeters, and Di is the diameter of the impression in millimeters. Details. The hardness test measures the resistance to . https://drive.google.com/file/d/12sSjLy6Zj5u6GovrGKXWSIPz3RF03lKp/view?usp=drivesdkBrinell Hardness Description. The Brinell hardness test uses a ball indenter of diameter, D, which is pressed into the surface of the test piece using a prescribed force, F. The time for the initial application of the force is 2 s to 8 s, and the test force is maintained for 10 s to 15 s.Brinell Hardness Number Test Formula BHN = (2*P) / [ (pi*D)(D - sqrt(D 2 -d 2 )) ] For example, when Loda force is 3000 kilogram force, steel ball diameter is 10 millimeter, depression diameter is 9 millimeter, the Brinell Hardness Number (BHN) will be 33.87331668681452.

The ratio of testing force \(F\) and the indentation surface \(A\) (spherical segment) serves as a measure for the Brinell hardness value HBW: \begin{align} \label{brinellhaerte} &HBW=\frac{0.102 \cdot F}{A} \[5px] .

Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information .Brinell Hardness Number Test Calculator. Material Science Testing Equations Formulas. Solving for Brinell Hardness Number. Inputs: load (P) steel ball diameter (D) depression diameter (d) Are you able to help others? Share this page. . The Brinell Hardness Number (BHN) is calculated as follows: . . Hardness Test and Formula. Hertzian Calculator - Line Contact: Online. Hertzian Stress Calculator - Elliptical and Point Contacts: Online. Tribology Companies. i-TRIBOMAT: The European Tribology Centre. Rtec Instruments.The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. The diameter of the resulting permanent impression in the tested metal is measured and the Brinell Hardness .

The Brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test piece. The Brinell hardness increases with the applied force required, and decreases with the diameter of the indentor.What is a Brinell Hardness Test? The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to 3000Kgf, for a specified time period, usually between 10 and 30 seconds. . (BHN) using the following formula: 7. Reporting .

The Brinell hardness test uses a spherical indenter which is pressed, by a precisely controlled force – most commonly 3,000 kgf – into the material being measured. The force builds between two and eight seconds then is sustained for several more to ensure that the indentation is a plastic deformation (see footnote). The diameter of the .Brinell hardness scale, known as the Brinell hardness number (BHN) measures the permanent width of indentation produced by a carbide indenter applied on a test material at a given load, for the given time. The below given is the BHN Formula that helps you in the BHN Brinell Hardness Number Test on your own.As shown in Fig. 3.12, the Vickers hardness curve remains practically straight at all hardness values, whereas at hardness above 300 kg/mm 2 the Brinell hardness curve starts bending to result in a lower value and it diverges remarkably causing an unacceptable hardness value above 600 Brinell, where the Vickers test is considered to be a .The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .

https://drive.google.com/file/d/12sSjLy6Zj5u6GovrGKXWSIPz3RF03lKp/view?usp=drivesdk

The Brinell test, which is used worldwide, is a straightforward method of determining how well a metal resists deformation – there are several such tests and you can read more about them here. In this article we deal only . In this video we will be discussing hardness which is the resistance for a material to dent. I will be explaining what the equation is doing and I will be do.

Another advantage of the Vickers hardness test is absence of different scales, as compared to Rockwell and Brinnell tests. At low values (VH<~400HV), Vickers hardness was shown to be the same as Brinell hardness (see hardness conversion section). Schematic representation of the Vickers test is shown in Figure 1. How to derive the equation for brinell hardness number quora determining using a standard non destructive test you testing iso 6506 astm e10 zwickroell hardnesstest calculation schematic diagram of indentation scientific formula derivation disadvantages and limitations calculator bhn scale wikipedia most important ese gate ssc rrb mse bht solved introduction .

Standardization of Brinell Hardness Test Blocks Annex A4 1.3 This standard includes nonmandatory information in an appendix which relates to the Brinell hardness test: Table of Brinell Hardness Numbers Appendix X1 Examples of Procedures for Determining Brinell Hardness Uncertainty Appendix X2 1.4 At the time the Brinell hardness test was .

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

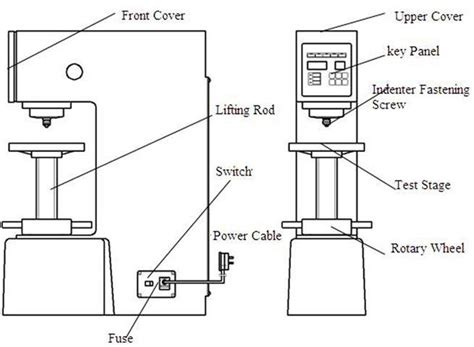

We would like to show you a description here but the site won’t allow us.J.A. Brinell proposed the first widely accepted and standardized hardness test in 1900. A steel ball is pressed into the surface of the specimen by a known load to plastically deform the material. . The Brinell Hardness Number HB is computed from the equation: where P is the applied load of 3,000, 1,500, or 500kg. D is the diameter of the .Brinell Hardness Description. The Brinell hardness test uses a ball indenter of diameter, D, which is pressed into the surface of the test piece using a prescribed force, F.The time for the initial application of the force is 2 s to 8 s, and the test force is maintained for 10 s to 15 s. This video explains the hardness of the material and how it can be tested using the Brinell hardness tester machine. Which is performed using Ball Indenter. .

An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide).For example, Brinell Hardness (HB) test is expressed by the pressure loaded on the press mark per unit area. The hardness of natural minerals is often tested by scratch hardness. Mineral hardness is divided into 10 grades, and the increasing order is: talc, gypsum, calcite, fluorite, apatite, orthoclase, quartz, topaz, corundum and diamond .

brinell hardness testing machine diagram

2/26/2024, 10:00:00 PM. . Watch NBA, NFL, MLB, NHL, soccer, and more for free with Sportsurge - your ultimate destination for live sports streaming. Watch Reddit HD sports .

brinell hardness test formula derivation|brinell hardness testing machine diagram